| We dye all our own wool - fine Australian merino tops - using earth

palette, landscape and Dylon dyes. We card the dyed wools separately and in blends. We

also dye silk top, waste, cap and bombyx to match and blend with the wool. We

lay up the wool conventionally to make half-felts.

|

|

|

| We use silk cap, top or bombyx to give

a lustre and resilence to the fabric.

This lay-up for the Summertime bag includes several layers of wool in different

directions, sandwiching some small off-cuts of scrap half-felt used for bulking.

These layers are felted around a plastic template, one after the other, to create

a seamless bag.

|

|

|

| The edges are carefully turned around the template

before the other side is added. When the first stage of felting is finished, the

top layer with the multi-coloured, half-felted cut-out patterns is applied. The

shapes all rest on a thin layer of half-felt so that they may be quickly

placed onto the wet felted bag. |

|

|

| After the bag has been sufficently felted on both sides of the template, the top edge is

carefully cut and the template removed. Then the bag is turned and the inside is

hardened with more rubbing, paying particular attention to the edges. The final

stages of shrinkage and fulling are completed with a blind. |

|

|

| Colourful half-felts are cut out and

positioned on a silk ground

The silk is cut out and sized to take shrinkage into account.

After felting the first half of the garment, the other side is laid up to

mirror the created pattern so that the neck edges and sides will match. |

|

|

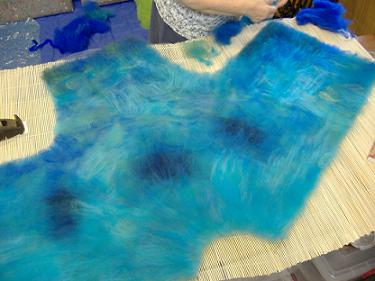

| Silk net cut to shape has been placed on the blind

and then covered with several thin layers of wool, blended as we go, to create

the under pattern. Bombyx silk is finely mixed and carded and laid over the surface of the wool tops.

This hightens the pattern of the wool and gives depth to the colours. A final

layer of silk bombyx creates the feathered effect. |

|

|

| Excess silk net is cut away from the edges after

achieving sufficient stability in the felt fabric during the rubbing stages.

Wool fibres will have penetrated the net to ensure a fine nuno felt after the

piece has been rolled in the blind. |

|

|

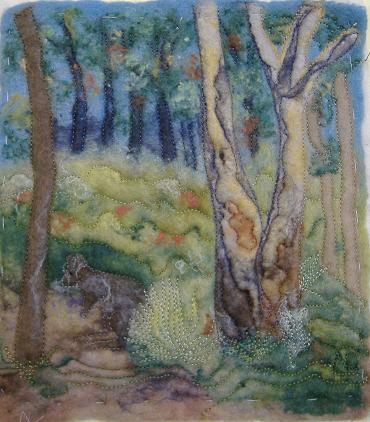

| Small pictures are created with half-felts and silk

waste, and carefully placed on a prepared half-felt ground. Simple machine

embroidery consolidates detail after the picture is felted. Small pictures like

these were the original sample pieces that Annette used to test her designs. They are

often made into glasses cases or small purses. Every major project has at least one

test piece. |

|

|

| The Elephant bag laid flat during the making-up

process. The pattern has been made using cut shapes in half-felt, with silk

throwsters waste for saddle detail and fine gold cord edging. The final

touches and beading are added by hand before the purse is sewn up and lined. |

|

|

| All seams are tacked before sewing, and Annette's

label is sewn in before the final hand sewing to complete the purse. The felt

has been backed by calico onto which the design has been drawn prior to sewing. |

|

|

| This very fine wool roving was laid in a coil and

space-dyed; when enough coils had been dyed, we assembled them on a length

of silk chiffon and felted them to make this simple but beautiful scarf. |

|

|